Thermal cycling is the test or process of cycling a material or device through two set temperature extremes usually at a somewhat high rate of change of temperature.

Thermal cycling test procedure.

However some test standards such as mil std 883 make the distinction between temperature cycling being performed as air to air testing and thermal shock being performed with the samples transferred between liquids.

To conduct the test all parts of the piping system will be involved such as pipes fittings joints and welds.

It is defined as an environmental stress test used to evaluate the reliability of the material or the product and to identify any manufacturing defects early by inducing failure.

The thermal cycling profile will replicate the same path to failure as seen in normal use.

Also called a heat dunk test the thermal cycling test procedure heats the assembly to 180 degrees celsius and then immediately dunks it into water.

Thermal cycling is another term often associated with performing temperature and humidity testing.

Our engineers test for thermal protection and water resistance.

Test method a104 b revision of test method a104 a test method a104b temperature cycling from board ballot jcb 00 16 formulated under the cognizance of the jc 14 1 committee on reliability test methods for packaged devices 1 purpose this test is conducted to determine the ability of components and solder interconnects to.

Thermal shock testing also called temperature shock testing or temperature cycling exposes products to alternating low and high air temperatures to accelerate failures caused by repeated temperature variations during normal use conditions.

The length of exposure time and environmental extremes depend entirely on the type of product and its intended application.

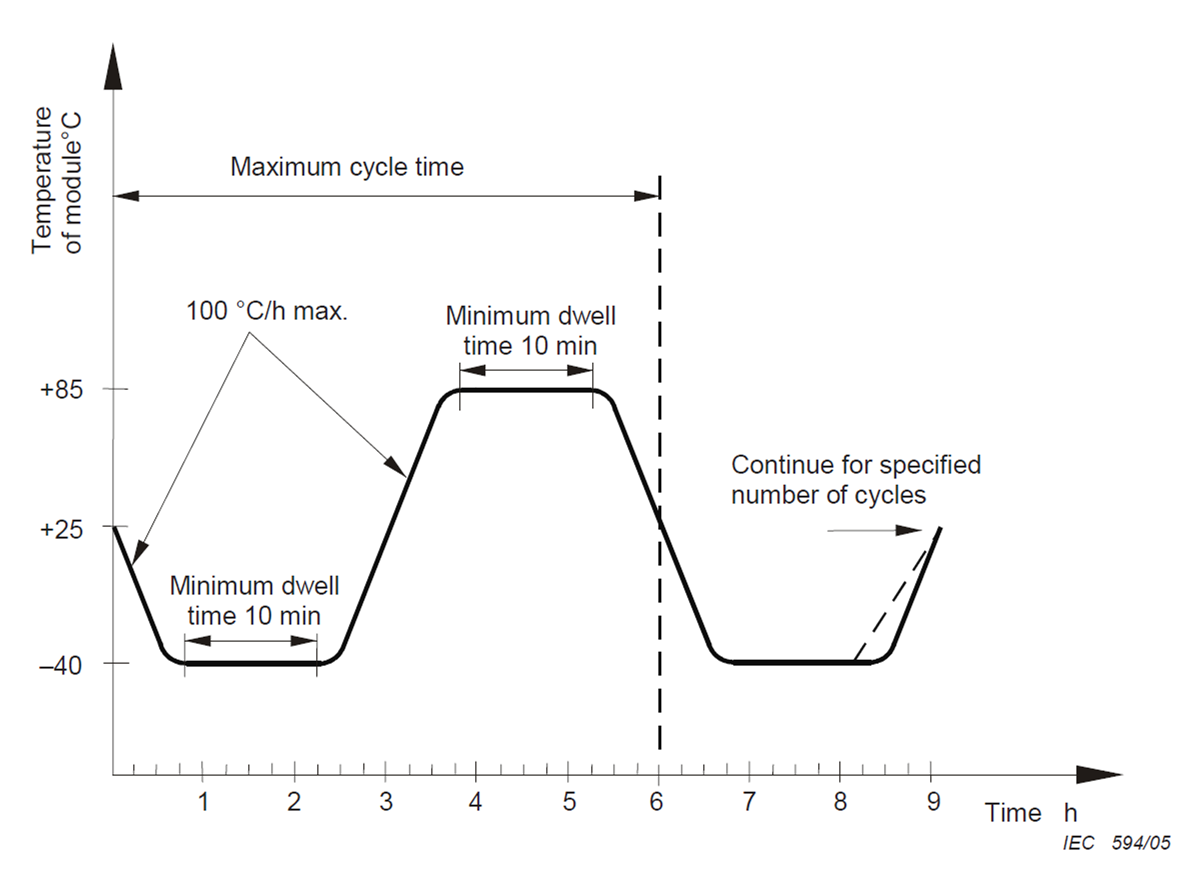

The transition between temperature extremes occurs very rapidly during thermal shock testing greater than 15 c per minute.

It involves exposing test subjects to a controlled cycle of varied periods of hot cold and wet dry.

It should be noted that temperature cycling may also be referred to as thermal cycling or thermal shock testing.

5 1 exposing a specimen to conditions of one directional environmental cycling can increase its moisture content until a decrease in material properties occurs at a specific number of cycles.

Thermal cycling test can verify the quality of design of the parts raw materials manufacturing procedure and installation process.

Thermal cycling test is the most important performance test for hot and cold water piping system.

Thermal cycling testing assures your equipment meets the necessary standards.

Thermal ovens require a hold time at an isotherm to assure all samples achieve the test temperature.

This very brief introduction to thermal cycling and the ways it can damage your product implies that you must understand the specific failure mechanisms before designing your thermal cycling based life test.